clock factory product and raw material quality and product checking

Zhangzhou Hengxiang Electronics Co.,Ltd. We are a professional manufacturer on LCD clocks, LED clocks, Weather station clocks, Radio controlled clocks, digital promotional items,etc. In order to controll the product quality, our company check the quality of raw material/mass products according to the AQL.

1. What is the QC?What are the responsibilities and functions of the QC inspector?

A, QC is the operation techniques and measures taken to meet the specification or specified data requirements.

B, the responsibility of the QC inspector is to inspect the finished products, raw materials and auxiliary materials as required.QC is very important to ensure the quality of the whole company, including the control and control of finished products, raw materials, auxiliary materials, etc., and the normal operation of the square and quality system.QC first appeared in the history of quality management. It is the most basic requirement of quality management for products to be shipped after inspection.The function of QC is to make statistics and analysis for the control and manufacturing process data of products in the process of production and processing, and provide the relevant information and data to other departments.

2. How is the product quality inspected in the operation of the company's quality system?

A. Definition of decision:

Heavy defects:

A. The product can not be used normally, such as: crash, missing scratch, no sound, no function of buttons, no backlight, lack of original function of the product, poor function or hidden danger caused by jailbreaking, obvious defects in appearance, etc.

B. Disadvantages that may cause harm to users, such as sharp edges of shell that may cause harm to human body, etc.

C. Apparent scratches, stains, miscellaneous spots, uncleanness, etc.

D. Customers have other special requirements

E. Stitch welding, high current, impurities, etc

Minor defects: defects that may be noticed by customers but do not affect their use or distribution.

Judgment Basis:

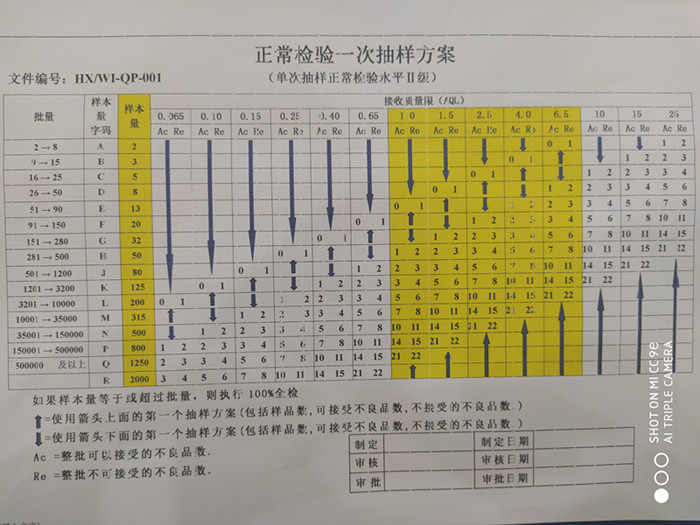

According to AQL quality sampling inspection standard:

Heavy defects: AQL 0.65

Light defects: AQL 1.5

Commonly speaking, it is heavy defect 2 accept 3 retreat, light defect 5 accept 6 retreat.

B. Decision Angle:

The appearance plane of the display screen or product should be about 30cm away from the eye between 45~60 degrees from the viewing Angle to check its display and appearance.

C. Inspection content

A. Appearance inspection of the product

The fuselage is deformed, misplaced, damaged, cracked, appearance scratches or stains, black spots, color difference, spray, shrinkage, large or uneven clearance, button/push button inverted, poor screen printing, less screws, clamping lines, glass fixation, inner sound, protective film is not removed, the inner membrane is not torn, etc.

B. Functional inspection of the product

Crash, lack of scratch, key/gear no function, card key, functional disorder, poor feel, no sound speaker, abnormal sound, lack of function, can not charge, no memory function, light stroke, uneven stroke display, backlight color, dark backlight, light leakage.